Optimized processes with automated and tactile measurement technology from ZEISS

Volkswagen plans to offer 70 percent of all cars produced as fully electric vehicles by 2030. Despite this enormous change to its product portfolio, Volkswagen’s commitment to quality remains unchanged. “Our components must meet high quality standards, whether they are combustion engines or electric motors”, says Holger Giersberg, sub-department head for quality assurance in the foundry and machining division at the Volkswagen plant in Kassel.

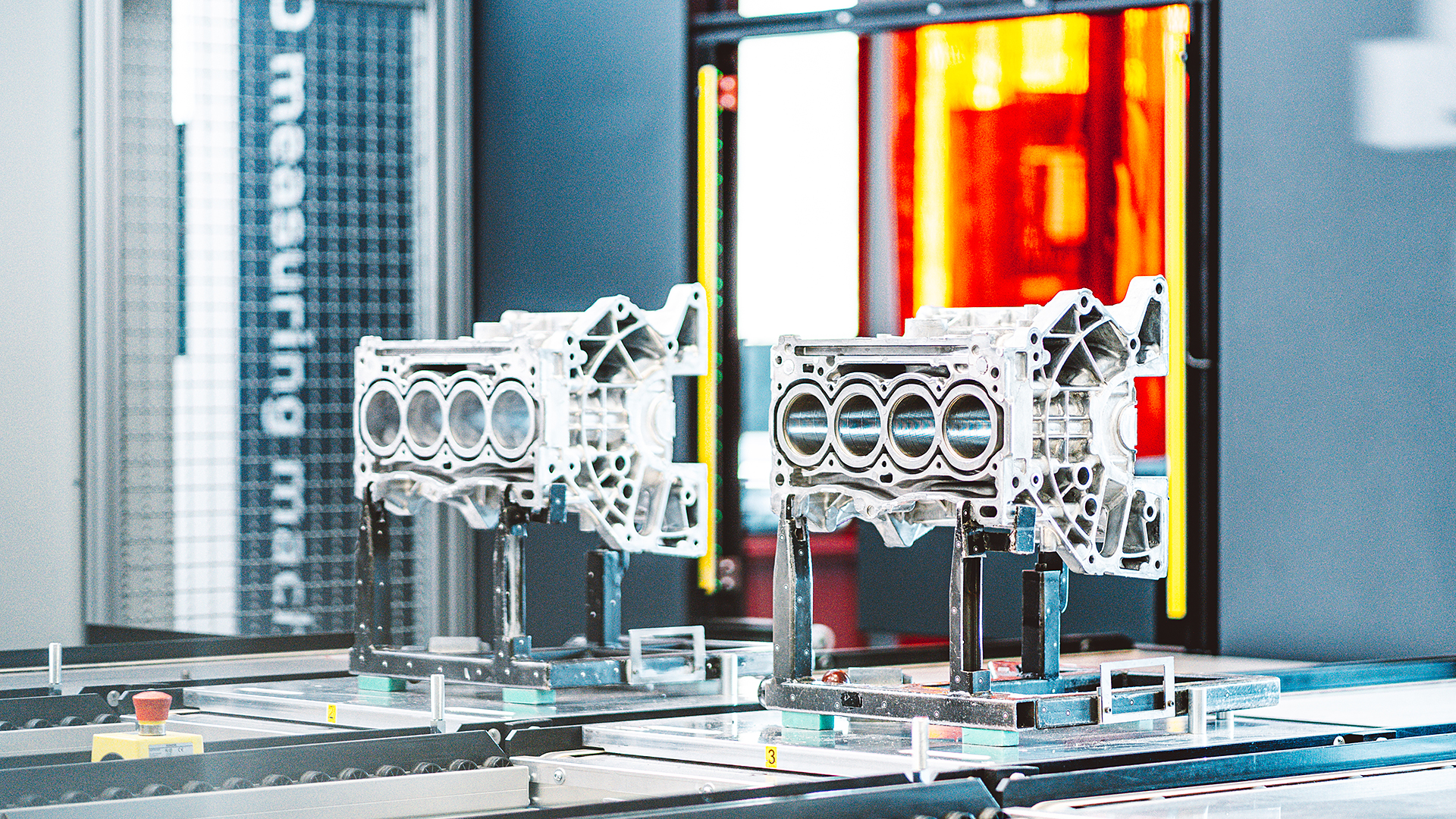

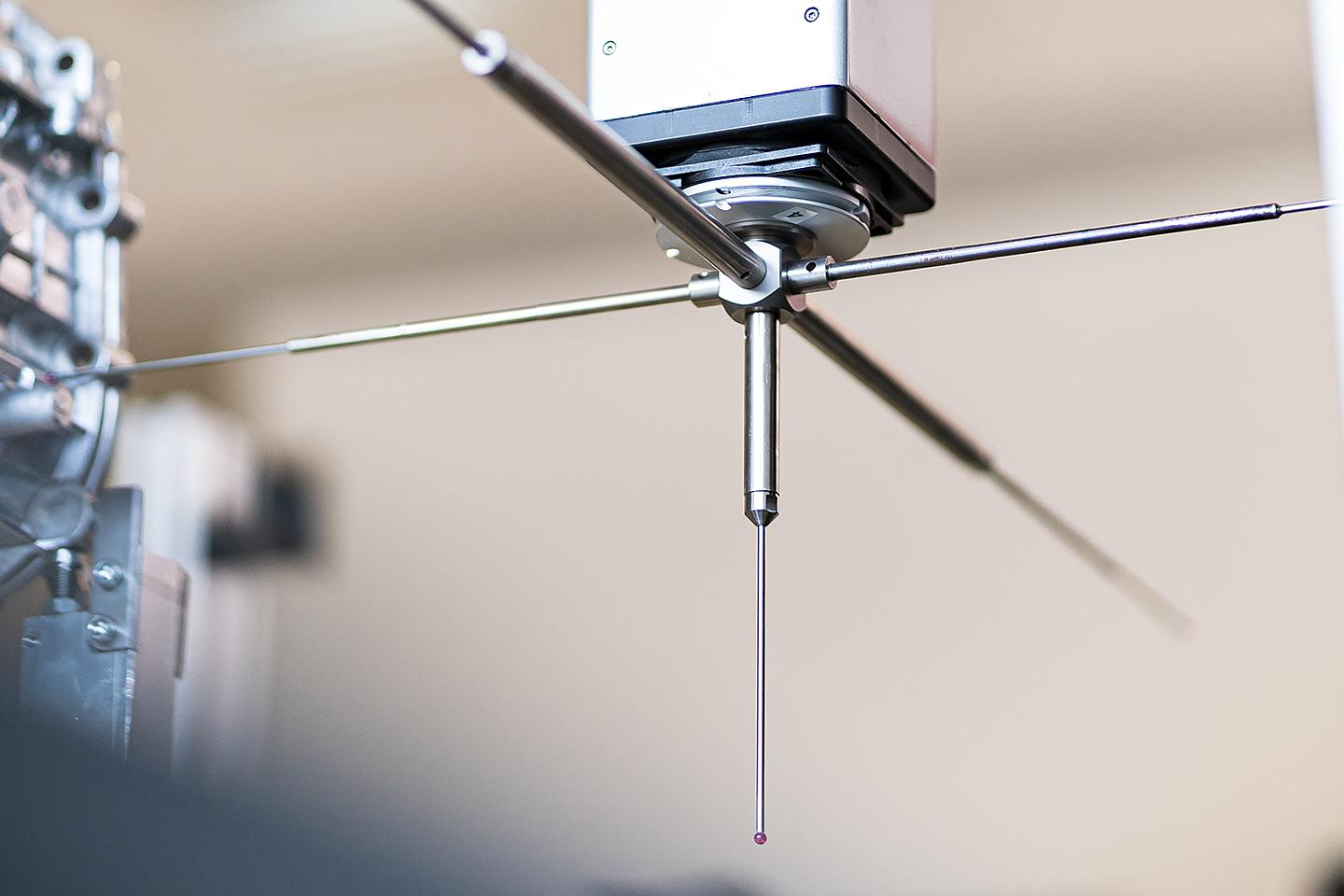

The Kassel plant’s foundry produces cylinder crankcases, gearbox housings, and housings for electric motors, among other parts. In three-shift operation, the quality assurance department inspects almost 200 delivered components every day. Special measurements are also carried out on an ad hoc basis, for example at the start of the production of new products. Volkswagen in Kassel has relied on ZEISS PRISMO coordinate measuring machines (CMMs) for many years. To shorten throughput times while obtaining more information during the production process, Volkswagen has also installed a ZEISS ScanBox — an automated optical 3D measuring machine that interacts with an automatic loading system from the ZEISS Integration Series comprising 14 set-up stations. The results speak for themselves: “The flexible networking of optical and tactile measurement technology has increased capacity by 30 percent”, reports Holger Giersberg.

Holistic quality assurance at the Volkswagen foundry in Kassel

Experience ZEISS PRISMO and ZEISS ScanBox in Europe’s largest light metal foundry

Automated system combines optical and tactile measurement technology

In a large room in the foundry, the delivered cast parts are ready for inspection. First, the components undergo a visual inspection, followed by X-ray testing. Finally, quality assurance staff measure the components using a system comprising several ZEISS PRISMO CMMs and a ZEISS ScanBox optical 3D measuring machine. “We inspect at least one component from each die casting machine per shift, which equates to 64 or more inspections in an eight-hour period”, explains Gerd Guhde, Quality Assurance Planner at the foundry.

Before the new ZEISS complete solution was implemented, employees worked through their inspection plans using three ZEISS PRISMO CMMs and a manual loading system. “The process was not yet optimal because employees had to wait for their turn to measure their workpiece”, Guhde explains.

Volkswagen in Kassel has long relied on ZEISS PRISMO CMMs and recently boosted production efficiency with the addition of a ZEISS ScanBox, an automated 3D measuring machine with advanced loading capabilities.

Faster and easier to achieve a more comprehensive result

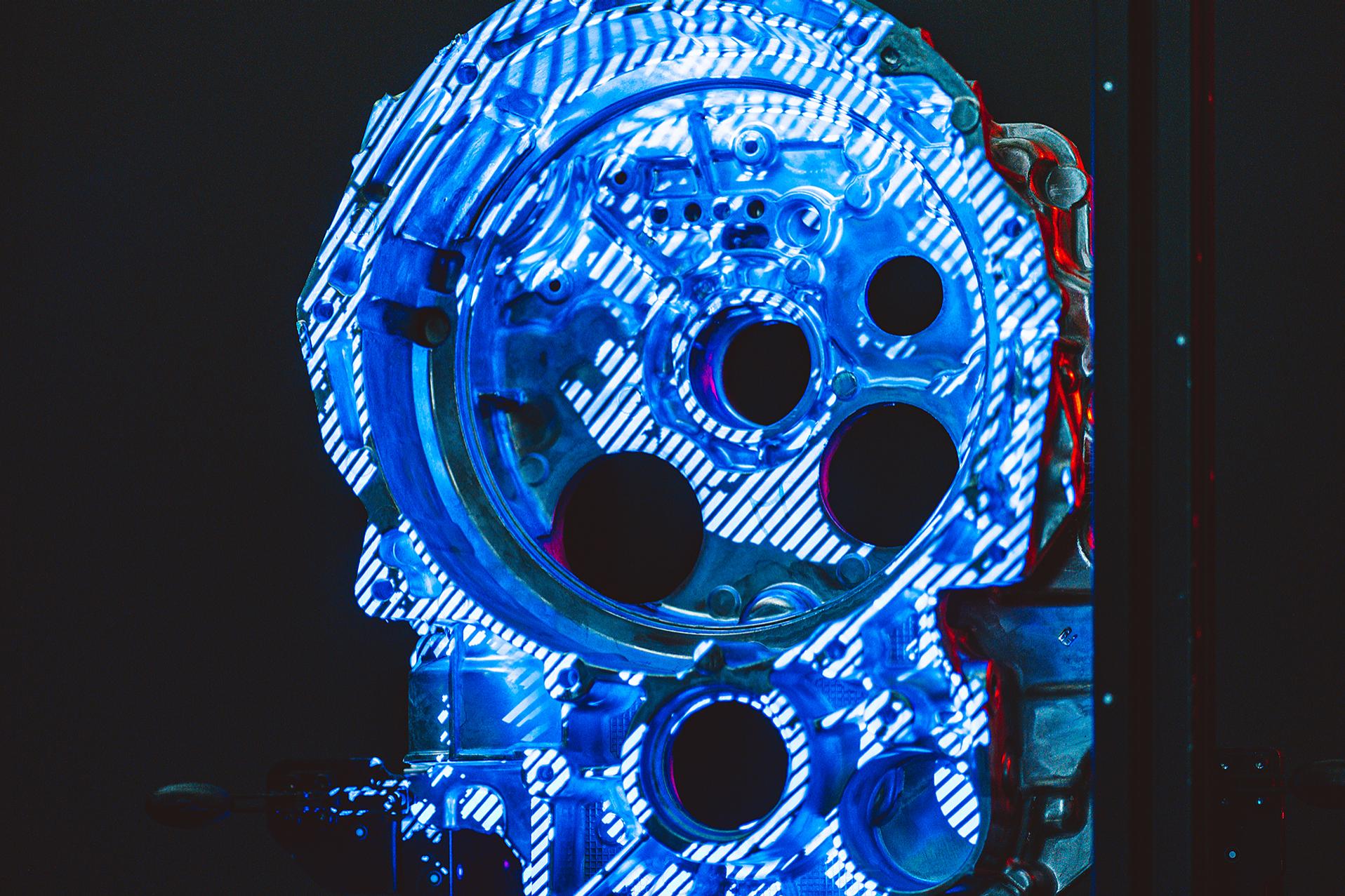

This system setup optimizes the utilization of the available measuring machines. The speed and quality of the measurement results have also improved. “Another advantage is that we can quickly record important measurement data optically in a single process and supplement missing data with tactile measurements”, explains Rene Bednar, a measurement technology inspector in the foundry’s quality assurance department. “This allows us to quickly obtain a complete measurement result for each component and recognize errors at an early stage, before they can have a negative impact on the rest of the production process.”

Furthermore, thanks to the ability of combining all measurement technologies of the ZEISS IQS portfolio into one solution, all the results of the optical and tactile measurements are summarized in one report. ZEISS PiWeb reporting and statistics software with an additional integrated false color display is used for this. The system can also be used by employees without metrological knowledge.